Equipment to Build Fibre Lasers

This is an equipment guide for those who want to get into building ultrafast fibre lasers. Of course, if you know what an ultrafast laser is or a fibre laser, you are likely familiar with most of these equipment but it's always good to make (or read) a summary for orientation.

So, let's dive into it!

FIBRE PROCESSING TOOLS

Speaking of fibre lasers, the first thing which you will need to consider is a fibre splicing equipment. Splicing optical fibre needs multiple equipment: at least fibre strippers, cleaver, fusion splicer.

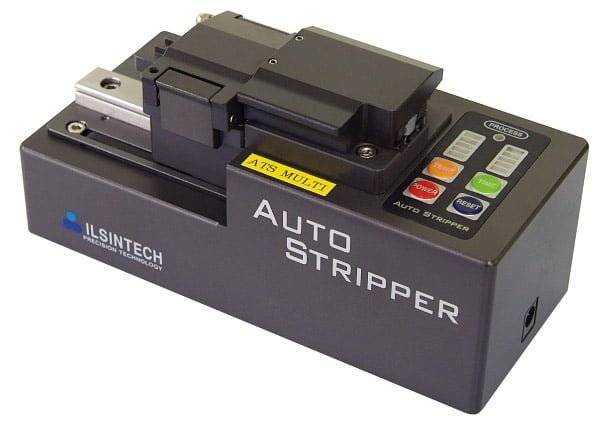

Fibre strippers are available numerous types (chemical, CO2 laser, hot air, mechanical ..) and they are used to remove the plastic coating from the glass cladding of the optical fibre. Some coatings are higher index others are lower index than the cladding depending on if you want or don't want to couple out light mistakenly or intentionally coupled into the cladding. Hot air or CO2 lasers can often leave charred pieces of plastic which can absorb light and cause hot spots. Mechanical strippers can be as simple as specially pliers or a blade working like a pencil sharpener - the disadvantage is scratches remaining on the surface. Chemicals are a health and safety issue, work slow and rather uncontrollably but do the job.

Once of the best ways to strip an optical fibre

Once you got rid of the plastic, you need to "cut" the fibre. This is in most cases a mechanical cleaving tool, scoring the fibre on the side and causing a controlled crack by mechanical tension. When choosing the equipment you will need to consider the cladding diameter of the fibre you need to strip. In some cases it could be useful to make an angle cleave, meaning that the light backreflected from the end face of the fibre will not couple back efficiently to the core.

I believe the CT-30 is a very popular choice when it comes to cleaving

After the fibre is cleaved you sometimes want to inspect the end face. There could be chips, unacceptable cleave angles or other damages you want to see. Often a simple Michelson interferometer is used for inspecting the fibre end. These devices are rather simple but because they are interferometers they often cost a lot. Check out for instance this one (GL16) from Thorlabs: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=12195 . This step is often not needed at all. Splicers can also measure at least the angle given the fact that the cleave angle can have considerable contribution to splice loss.

The next equipment is the splicer itself. The two main companies offering fibre fusion splicers are Fujikura and Furukawa. Both Japanese companies. The working principle is rather simple: an electric arc produces high enough temperature to melt fused silica (ca. 1600°C) and once it's molten the two fibre ends are pressed together. The arc electrodes get corroded over time and need recalibration daily to maintain splice quality. Recently the CO2 laser splicers or the 3SAE ring of fire is also used which need much less maintenance but at the same time cost much more than usual splicers. An arc fusion splicer from AliExpress can cost as low as a 1000 euros but if you want to be able to splice polarization maintaining fibres you need to reach as deep at 20-30 000 euros in your pocket. Furthermore, CO2 or RoF (Ring of Fire) splicers can cost 40-70 000 euros. I believe Thorlabs has an old style machine which is a bit of an exception and using a carbon filament to heat up the fibre - very unreliable and maintenance intensive equipment (yes, I'm talking of the Vytran).

A PM fusion splicer from Fujikura

Some of these splicers are often capable of fabricating mode field adapters or splicing large diameter components (like endcaps) to small diameter fibres but if you want to make the good stuff you might need to invest into a tapering machine or something custom.

The best on the market tapering machine from 3SAE

Some companies often do their fibre Bragg gratings or optical fibre based sensors in house which could need either a UV laser and deuterium loading of the fibre (photosensitive or similar fibre) or a femtosecond laser to inscribe these structures directly.

Once you have your structures and splices in place, you might want to inspect the losses in your fibre. There are two very similar methods for that: OTDR (optical time domain refractometer) or the OFDR (frequency domain). The advantage if the OTDR that it's cheap (couple hundred euros) and that it can detect issues on a long piece of fibre (kilometres). The principle is rather simple, it's almost like a LIDAR: you send pulses into the fibre and check how much light is coming back in the time domain.

The OFDR is a more complicated equipment and often costs up to 100-1000 times more than the OTDR but in exchange you can measure splices on the micrometre scale and detect a lot other details (bend losses, fibre irregularities etc). Range is limited. Often the much higher price is not justified for the non-research applications.

LASER TEST EQUIPMENT

Aften the fibre handing and splicing is taken care of, you can start building your laser. If you still remember we wanted to build fibre lasers..

For the optical part you want to have a thermal or photodiodes based power measurement head and the handheld device itself. Popular suppliers are Gentec, Coherent, Thorlabs, Ophir or eBay. Prepare to pay a couple thousand for the set.

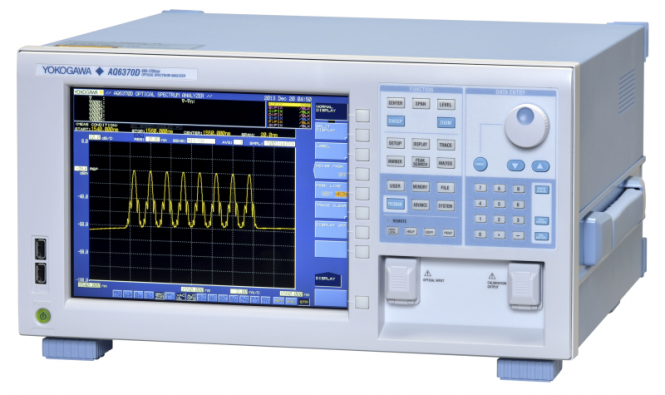

The optical spectrum of the laser can tell a lot about nonlinear effects happening, mode locking or q-switching, filters not having the right specs so you better replace your spectrometer with an optical spectrum analyser. Yokogawa is one of the best on the market. These devices are rather complicated optical assemblies so prepare to pay 50-150 000 euros for this piece of equipment.

An optical spectrum analyser from Yokogawa - highly recommended

If we are talking of spectra, a photodiode and a RF spectrum analyser, an oscilloscope will be useful. Photodiodes are often limited by bandwidth (the rise time of the electric signal in response of a very short optical excitation) and often you can get nanosecond rise times. This is simply the limitation that a photodiode is a diode and it has a finite electrical capacity. Just like capacitors, this one will also have some lag when charged upon incoming photons. Nanoseconds won't be enough to resolve very short optical pulses but using the oscilloscope you can analyse the pulse spacing and trains. Using the RF spectrum analyser (which is an oscilloscope with an automatic Fourier transform function on) you can analyse the bunch of pulses instead of looking for only a couple of them. A baseline in the mode locking and side lobes will be the measure how good your mode locking is and how many pulses are there circulating in the laser cavity. Some of these devices might cost 10s of thousands of euros.

An excellent RF spectrum analyser from Rhode & Schwarz

For analysing the shape of the pulses itself one needs to use an autocorrelator or FROG. The FROG gives more information about the pulses but in most simple cases an autocorrelator will do just fine. There's not enough space here to explain in detail how these devices work. Let's just say they split the pulse, delay one of the split pulses and at the end they overlap again the split pulses inside a nonlinear crystal (second harmonic generation or similar). Depending on the delay, you get an average second harmonic intensity larger or smaller on the detector. Because the delay depends on the length of the pulses, you can practically measure how long the pulse is. APE Pulsecheck is a solid industry standard for this task and has been for at least the last 15 years. It will cost about 20 000 euros.

We have now measured most of the pulses and pulse trains but there are still some properties which we have not analysed. A beam profiler will be used to measure the beam diameter and the beam quality of the laser. Interestingly, the spatial energy distribution inside the laser beam will determine how much it expands over a certain distance. The closer it is to a normal distribution, the smaller the divergence. These devices are basically nothing but low megapixel cameras. Low resolution is not necessary but will be needed if you want to have a 100fs frame rate. Also, I guess at the time of the development 4K was not in fashion yet.

Does this Ophir beam profiler look like a FLIR CMOS camera?

The final, often used equipment on my list is a thermal camera. Using a thermal camera we can often find lossy components, identify a splice which did not go well or point at active fibre sections which are not heatsinked properly. It's not crucial unless you have at least a couple watts of power but very handy..

Example thermal camera A35 from FLIR

Other than the actual equipment, one needs to consider many consumables. If you have a laminar flow cabinet or cleanroom, that will need periodic measurement or filter replacements. In-house pressured air, isopropanol alcohol (for cleaning), cleaning wiped and buds, replacement electrodes for the splicer, tapes, cleaver blades, sharps box for cut-off fibre ends ... are all count as consumables. In the beginning you will need an optical table (maybe even with damping), other tables, lamps, tools, microscope(s), fibre end microscopes and ESD equipment too. If you are working with a class 4 laser, you will need laser safety equipment, interlocks, laser safety officer too.

Black mats on the workbench are particularly useful for fibre optics because the optical fibre will just disappear on a white background.

SUMMARY

Starting to produce or develop lasers, especially fibre lasers .. especially ultrashort pulse fibre lasers is expensive. My estimate for the total investment needed is around 300 000 euros. It's still not that much as starting a semiconductor fab but it is a major barrier for small companies to start developing and producing lasers. If you are thinking of opening up a laser fab, we hope list will surely help you to do so (or to discard the idea due to the high cost).

If you lost the thread somewhere above and jumped straight to the summary, here is the list of tools we have been going through above: