Fiber Laser Galvanometer Scanner - A simple simulation model

Galvanometer scanners are often used for laser marking, engraving, cutting .. purposes. The system itself is optically a rather simple assembly: two mirrors which can be tilted individually using small electric motors.

The laser beam is usually 1064nm, 532nm or 355nm wavelength. Light at 1064nm with high intensity and low divergence can be routinely generated from a fiber laser. This is then sometimes frequency doubled or tripled because some materials absorb green or UV light better than infrared or because the shorter wavelength will allow an even smaller focus spot size.. The divergence of the beam is around 0.3-0.4 mm mrad. This means that a 0.4mm beam radius, collimated laser beam would have a divergence of 1mrad (0.057 degrees). The beam is however collimated to about 4-6mm diameter (2-3mm radius) so the divergence even lower than that.

The collimated beam is deflected by the mirrors and focused by the f-theta objective lens. F-Theta objectives are flat field lens assemblies, made of 5-8 pieces of large aperture spherical and aspherical lenses. Simple lenses have a curved focal plane: the larger the incoming ray's angle, the closer the focal point to the lens. Additionally, aberrations will also increase with increasing angle and this will result in a larger spot size in the focus.

Compared a single spherical lens of 160mm focal length and a f-theta objective lens with 160mm effective focal length will have 1mm vs. 0.04mm spot size. So you really need a flat field lens.

F-Theta objective specification:

There are a couple of important parameters when it comes of choosing the right f-theta.

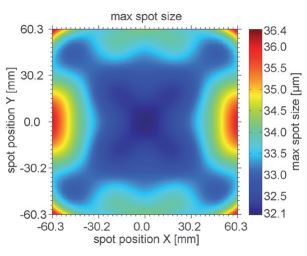

Spot size: The spot size (1/e2) in the focus is of course an important factor, this will influence the intensity of the processing beam and therefore limit what and how fast can be processed. Manufacturers often plot the spot size variation over the processing area. Note that the spot variation in the below typical example is maximum 4um (10%). Very small.

Maximum beam diameter: The spot size is calculated using a beam diameter. The larger the beam diameter, the sharper the focusing and therefore the smaller the spot size. If your laser beam is only half of this size, your spot will be double as large..

Working distance: If you have large parts you might want to check this. The working distance is the distance between the bottom mechanical part of the lens assembly and the focal point.

Scan area: This is the size of the area where the laser can be scanned used this lens. The larger scan area you need, the longer focal length you will have to choose and the larger spot size you will have in the focus. A 160mm focal length, 100x100mm working area lens vs. a 320mm focal length 300x300mm working area will give you 4 times smaller light intensity in the focus. Choosing a large area doesn't always worth it.

Ideal lens distance from the mirror: The lens should be ideally in a given distance from the second scanning mirror. You might need some spacer rings.

Wavelength: This is kind of obvious but I will list it here. The lenses are anti-reflection coated for a given laser wavelength +/- 10s of nanometers. Uncontrolled reflections inside the lens assembly might damage the lens or the mirrors.

Telecentricity: The beam comes out in an angle from the lens. If you need as low as possible incident angle, you will have to pay extra for a telecentric design.

Modelling an f-theta lens in a optical simulation model can be done in different ways. Often the manufacturer packs the design in a black box which is only accessible for the simulation software, but not for the user. The black box file is however encrypted and can be opened only from the same software which created the file. In most cases such a black box is not needed at all, it can be modelled with a "ideal f-theta lens". This approach doesn't consider of course aberrations, but the deviation won't be noticeable if the manufacturers optical design is good enough - which is in most cases as we've seen above. So in this model an ideal lens is used.

Beam Expander:

As stated above, to achieve the best spot size, you will have to make your laser beam diameter to the largest allowed size in the optic. Luckily designing a beam expander is easy:

1) Calculate the needed magnification. Desired beam diameter / your beam diameter.

2) Choose a lens with a short focal length.

3) Find a lend with focal length of the short focal length lens times desired magnification.

In this example I built a beam expander with 4x the magnification. So the first lens is a -25mm focal length concave lens and the second lens is a 100mm focal length convex lens.

It would work with two convex lenses too (Keplerian design).

3D galvanometer:

Some extensions allow with an extra lens and motor to change the working distance. This allows with appropriate control to mark 3D designs/objects layer by layer. Otherwise the 2D system has only a few (2-3mm) millimetres depth of focus. Anything which is not within this 2-3mm depth will not be processed properly.

These kind of laser scanning designs are advantageous because with smart design one can get rid of the f-theta objective completely, reducing the size of the machinery further.

Other accessories:

As we know the optics is not the only part of the laser scanning system. So operate it you will need a software which converts your desired marking/engraving design to a path the laser should scan. Then the path will be fed to a electronics point-by-point which will move the motors with high accuracy and give the laser signal when it should turn on and off during the marking. Low quality (understand: working with issues) systems are available for a few thousand dollars ($2000-$15000) depending on wavelength, power, laser type so it's getting more and more affordable for everyday users.

Important! Make sure you wear proper laser safety equipment when you are playing with a device like this.

P.S. If you want to see how this model is built from scratch, visit out YouTube channel.